//process

[1] ARABIC WOOD TYPE

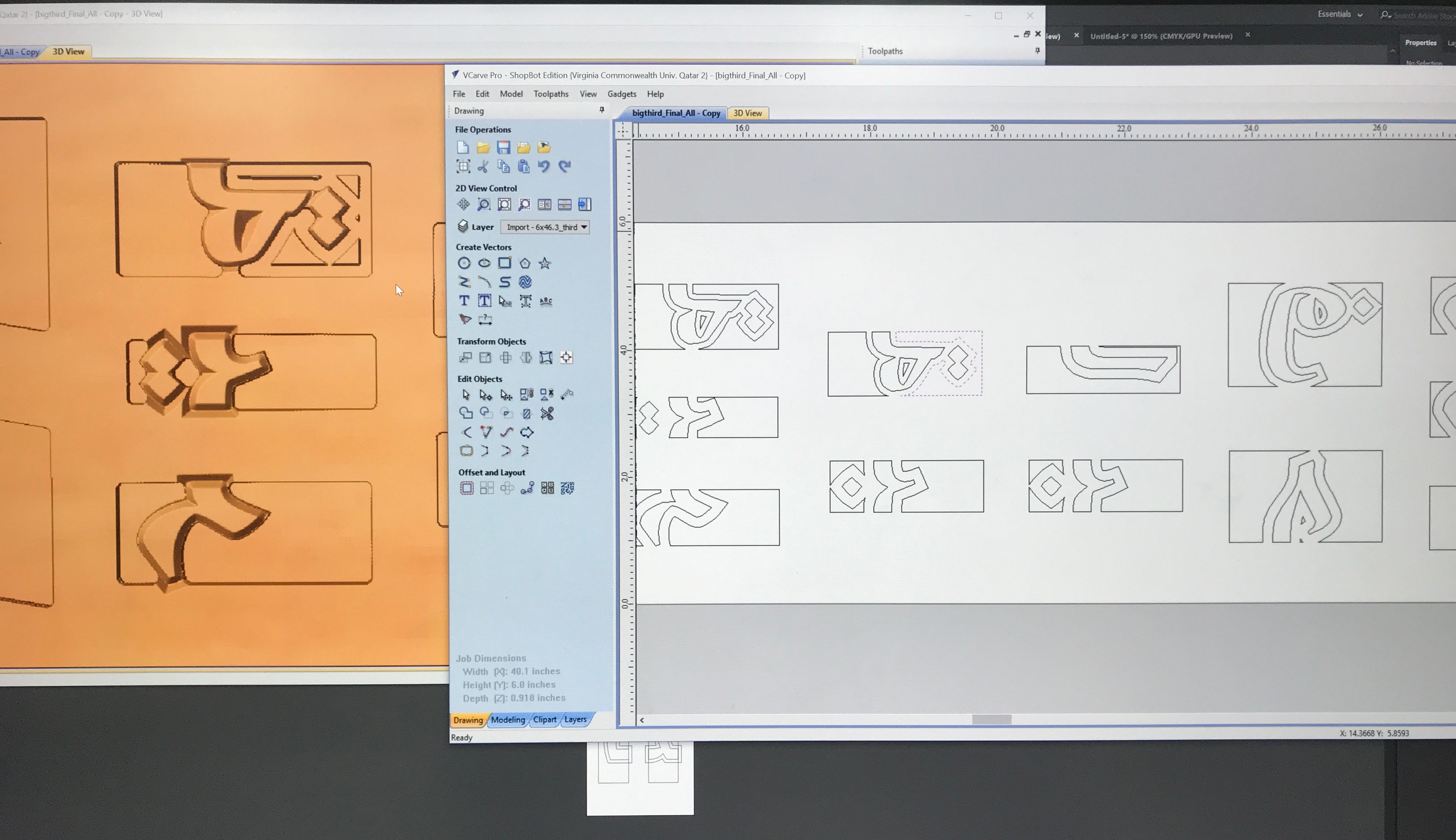

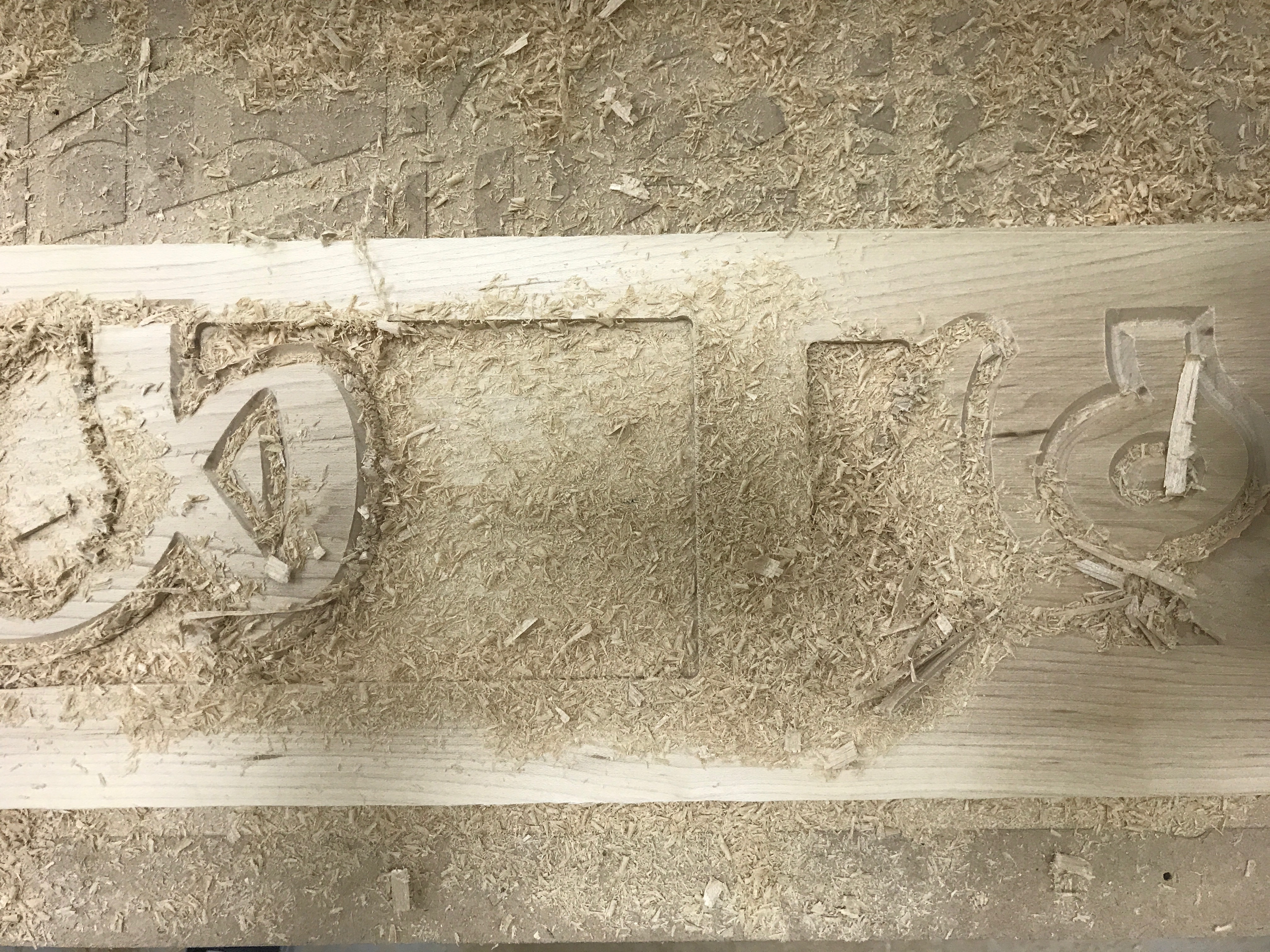

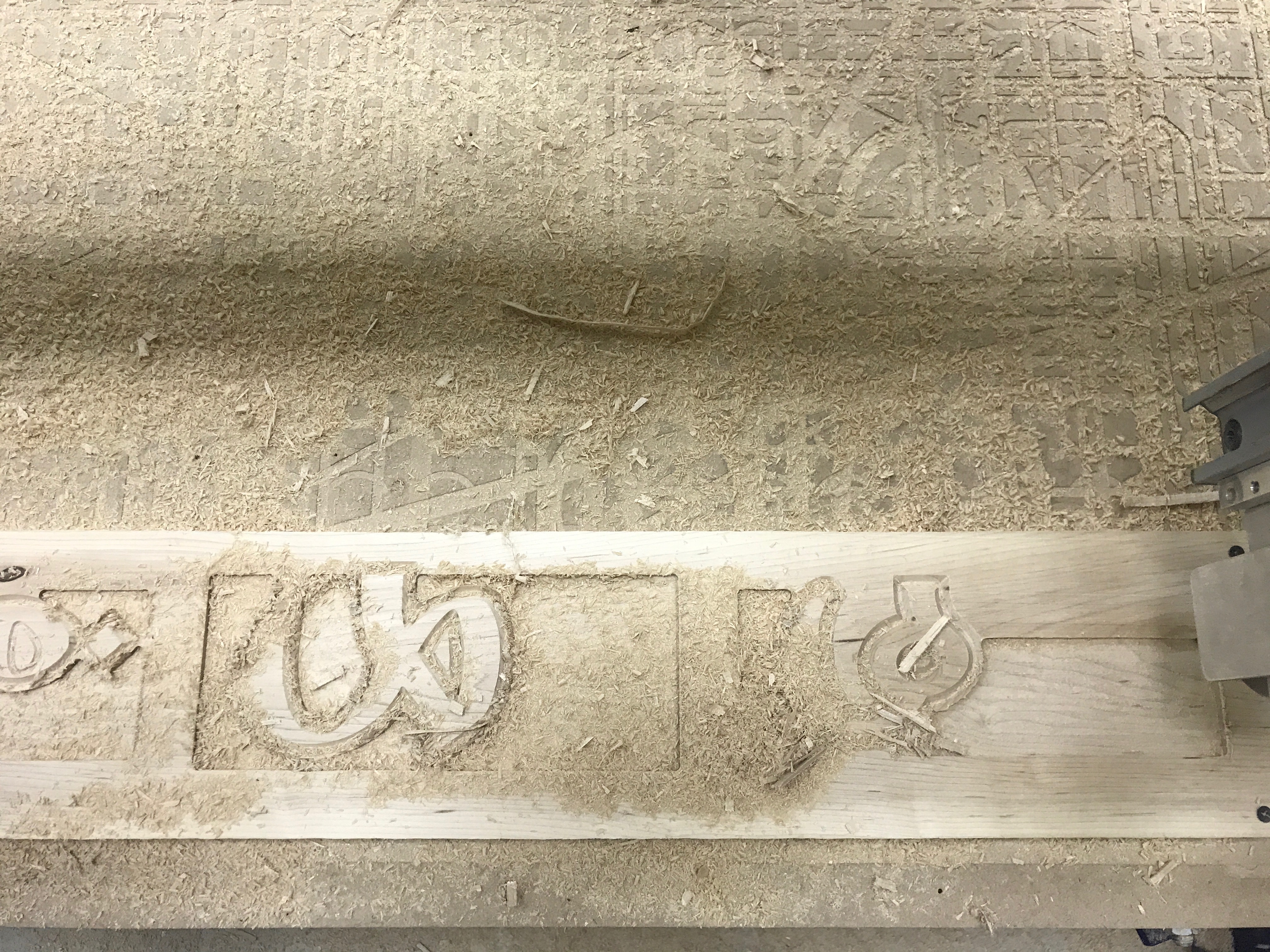

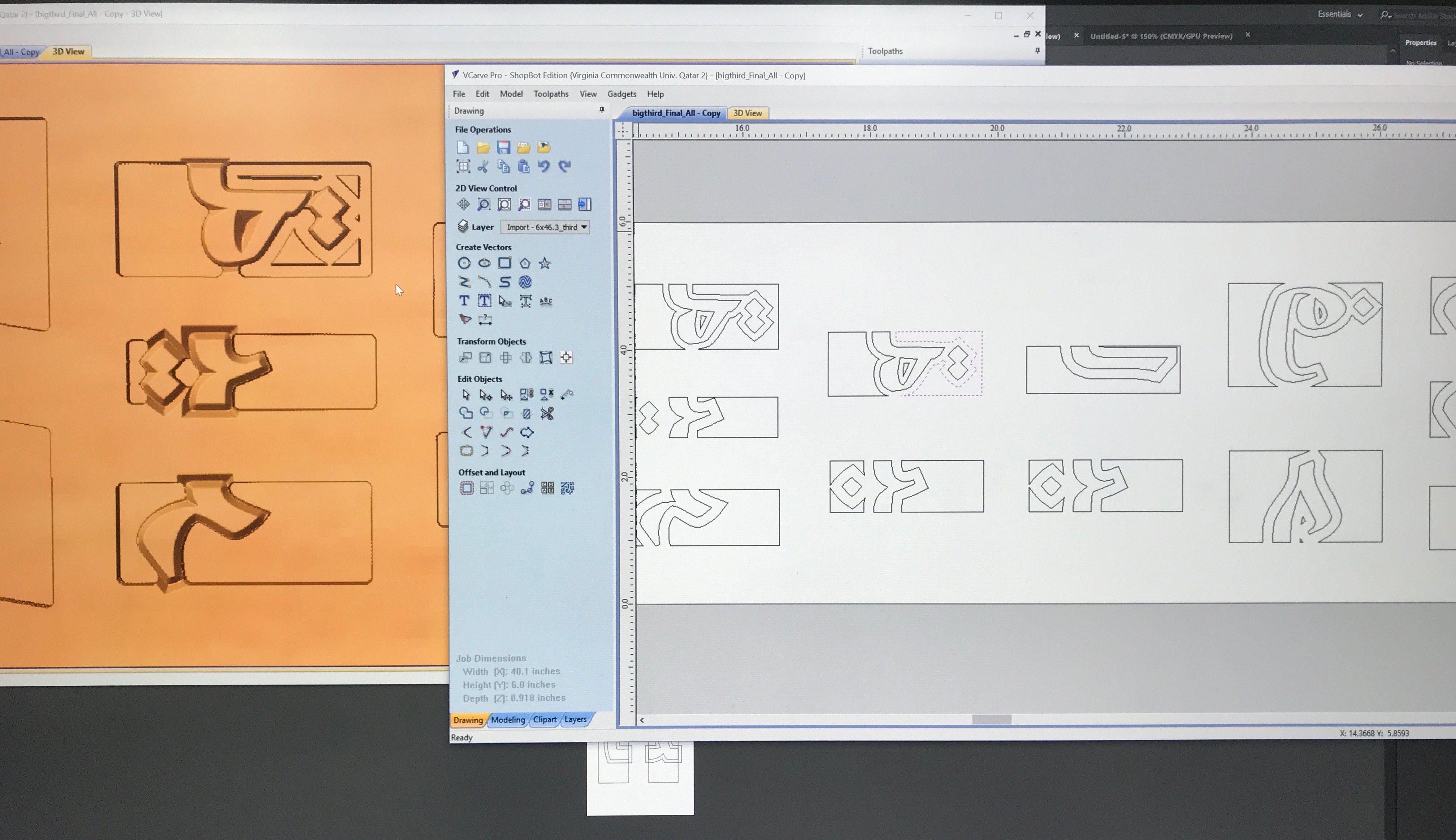

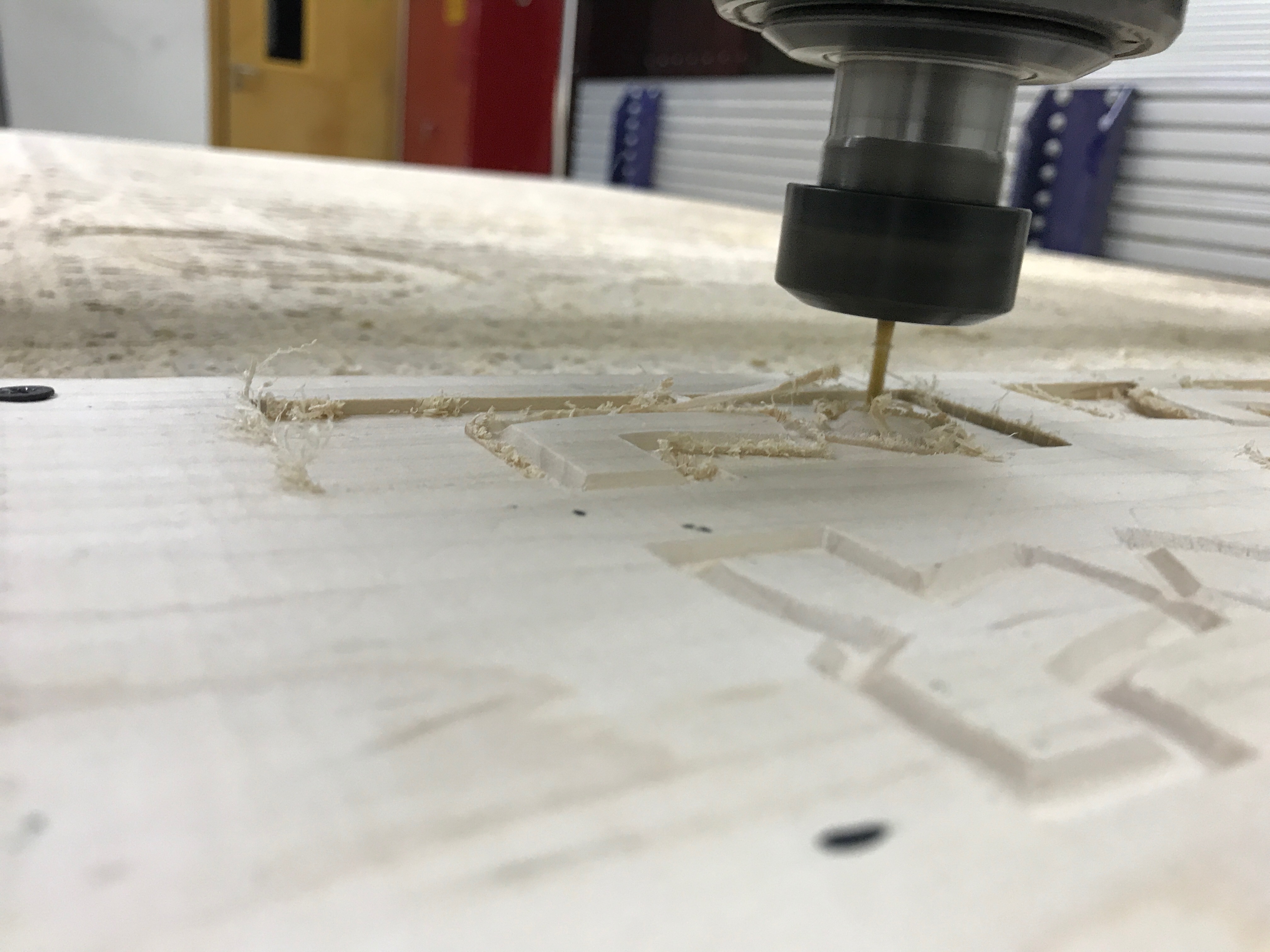

The process of creating the work went from choosing the typefaces based on the different arabic scripts and then modifiing the connections of some of the typefaces. Then digital files were created to prepare the files for carving using the cnc. The wood was first prepared and planed to type high and then carved on, lastly cutting and finishing in the woodshop.

The process of creating the work went from choosing the typefaces based on the different arabic scripts and then modifiing the connections of some of the typefaces. Then digital files were created to prepare the files for carving using the cnc. The wood was first prepared and planed to type high and then carved on, lastly cutting and finishing in the woodshop.

[2] PROOF PRINTING PRESS

The press was designed to be a proof press, the design is modified for a simpler version of a press as a DIY kit. most of the process working on this press was getting the measurments and sketching the parts and figuring out the mechanism. the press parts were produced using the cnc for some flat and 3D parts. it was then assembled using wood glue and stainless steel bolts and nuts.

The press was designed to be a proof press, the design is modified for a simpler version of a press as a DIY kit. most of the process working on this press was getting the measurments and sketching the parts and figuring out the mechanism. the press parts were produced using the cnc for some flat and 3D parts. it was then assembled using wood glue and stainless steel bolts and nuts.

[3] PRINTS

The prints were printed using the produced wood type. the inks used were letterpress florecent inks. the design of the prints was focusing on the form of the characters therefore no other elements were included in the prints.

The prints were printed using the produced wood type. the inks used were letterpress florecent inks. the design of the prints was focusing on the form of the characters therefore no other elements were included in the prints.